No more stress! Shuttering concrete floor slabs can now be done far more easily and without wasting wood.

Square timber and wooden boards are not.

Save on construction timber,

circular saw and disposal.

Today's frame formwork is highly modern and professional. But the way concrete floor slabs are shuttered with it is antiquated. As in the 1980s, square timber and wooden boards are still used for support, something that costs money. Not only does the timber have to be paid for, but working time is taken up moving it around and cutting it on the circular saw. And at the end, the timber needs to be disposed of – what a waste!

SEKI

Support Frames

Fortunately, there is a solution that makes all of this redundant: the SEKI support frame. No timber, no circular saw, no running backwards and forwards, no disposal and no wasting of resources. In the time it takes a construction worker to set up a single square timber support, three support frames can be installed without stress – welcome to the construction site of today!

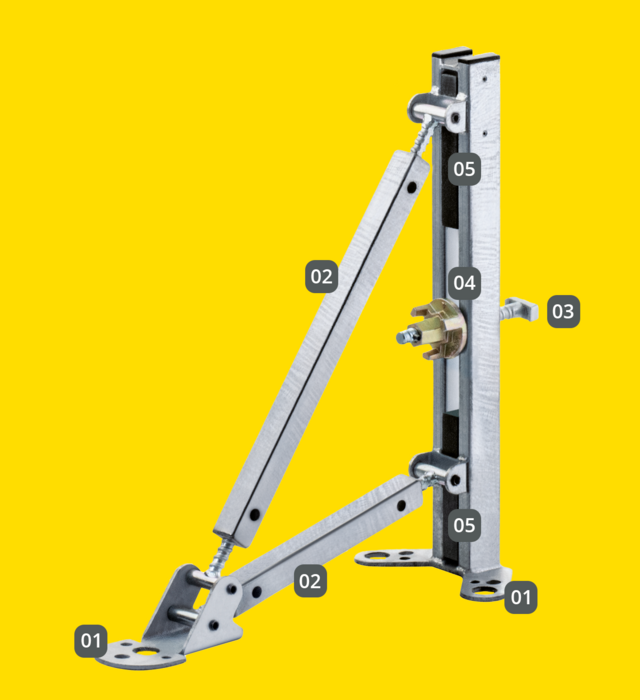

Easy to assemble

The SEKI support frame can be attached to framed formworks from different manufacturers as well as to wooden shutterings.

Easy to install

The height of the rear footplate can be adjusted, allowing height differences to be easily accommodated.

Easy to adjust

The support frame can be adjusted simply by rotating the double-threaded pipes using a carpenter's hammer (or by hand).

Easy to secure

Openings in the footplates allow the SEKI support frame to be firmly anchored in the ground using pegs, concrete screws or dowels.

Maximum

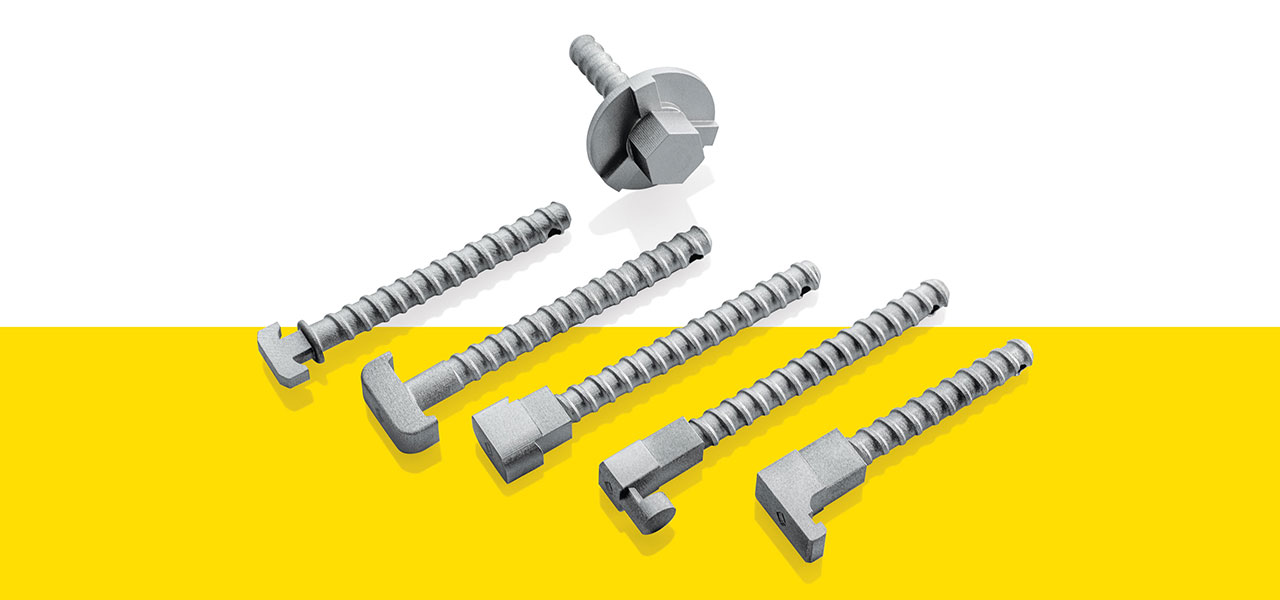

compatibility

Every system formwork manufacturer has its own mounting rail. This is why we have developed different hammer head screws – the right screw for every anchor profile. Contractors using different frame formwork systems simply need to change the hammer head screw in the SEKI support frame in order to attach it to another frame formwork.

Nothing

simpler!

I'm a constructor and developer through and through. I have often been annoyed by the unnecessary difficulties involved in shuttering concrete floor slabs. Supporting a frame formwork with square timber or wooden boards is a bit like fitting carriage wheels to a sports car. On top of that, it's a waste of time and money, not to mention the problems caused by uneven working spaces.

"What should the ideal support frame look like?"

I asked myself this question and thought about the requirements the support frame has to meet. It needs to be compatible with frame formworks from as many different manufacturers as possible. The connections to the various anchor rails on the form frameworks must be adjustable, and the support frame should also be suitable for use with wooden formworks. In addition, the support frame must take into account the needs of the construction site personnel: it should be simple to use, durable and safe. It needs to be adaptable to the usual concreting heights for concrete floor slabs and foundations of different heights (60 cm and 90 cm). The height of the rear footplate should be adjustable, so that the support frame can be firmly anchored even if there is a height difference, e.g. a projecting concrete floor layer. I incorporated all these elements into the SEKI support frame, and you will see the difference on the construction site.

EWALD KLÄS

Managing director, SEKI Schalungstechnik

Contact us

Do you have any questions concerning our products? In order to assist you, please fill in the contact form and give a brief description of your request.